MARATHON HEATER (INDIA) P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to MARATHON HEATER (INDIA) P.LTD.

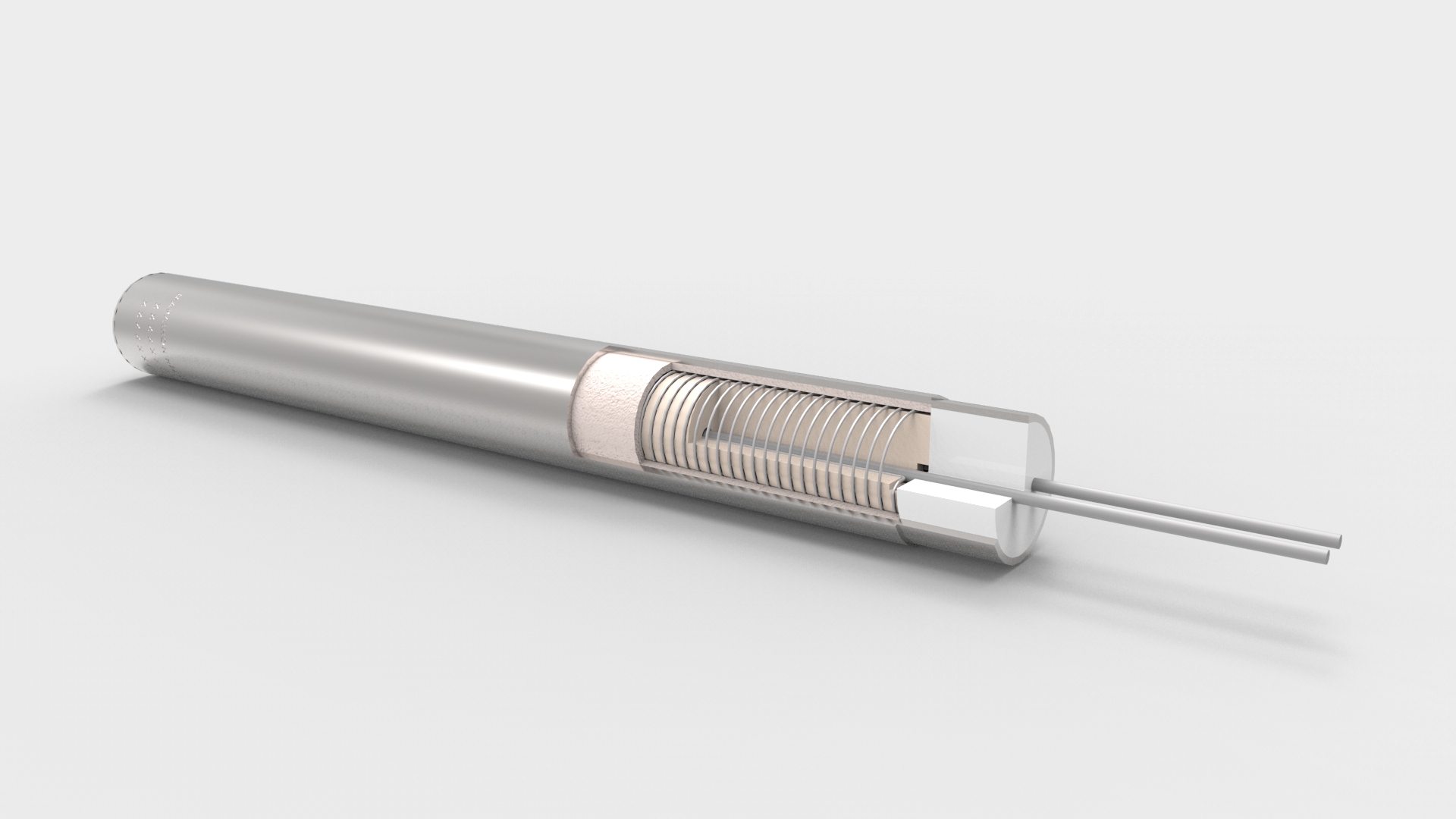

Thermocouple

Thermocouple is the most universal, expedient, and versatile device used to measure temperature. It is a sensor that measures precise temperature within a wide range. Manufactured by joining together two dissimilar metals at one end, the thermocouple alloys are usually in the form of wire. A reference junction is also included at the opposite ends of the parent material. By heating or cooling the junction between dissimilar metals, a temperature gradient is produced, which generates a voltage. This voltage is converted into units of heat calibration at the ends of thermocouple wires. The heat generated is converted into useable units that serve as input signals for controllers. Thermocouples are suitable to be used in temperature ranges from -200 to 2316 °C [-328 to 4200] °F. Widely used in high temperature applications, they are less expensive in most cases and can withstand higher temperatures than RTDs.

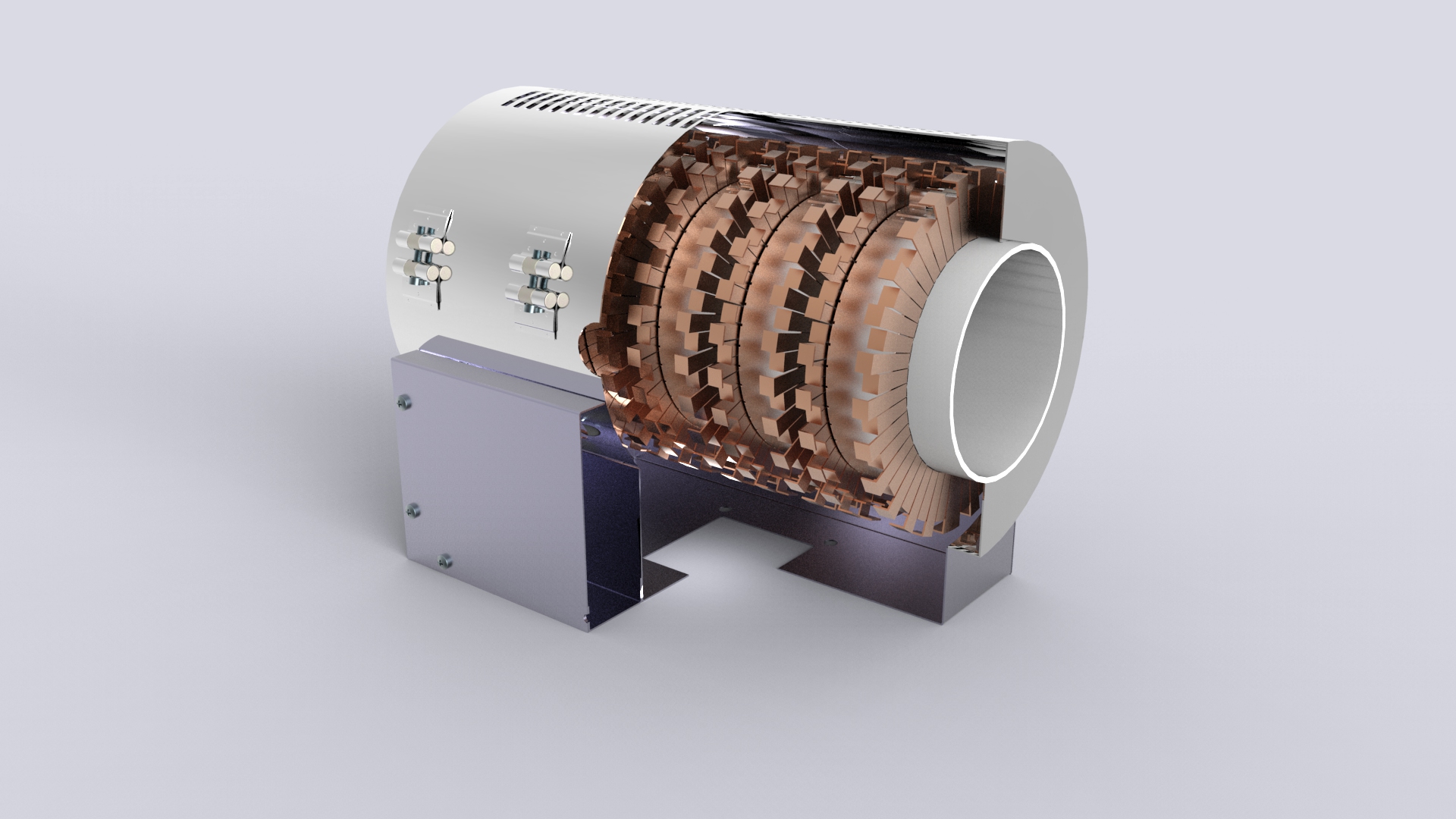

Resistance Temperature Detector

Resistance Temperature Detectors (RTDs) are temperature sensors composed of certain metallic elements whose change in resistance is a function of temperature. As the name implies, these are sensors used to measure temperature by correlating the resistance of the RTD element with temperature. A small current is passed through pure electrical wire and voltage which is proportional to resistance, is measured and converted to units of temperature. Manufactured by winding a wire (wire wound elements) or plating a film (thin film elements) on a ceramic or glass core, it is sealed within a ceramic or glass capsule. RTDs offer a wide temperature range (-50 to 500°C for thin-film and -200 to 850°C for wire-wound), so selecting the proper element and protecting sheath material is important for functionality. Excellent degree of repeatability, stability and accuracy has made RTDs a common name in laboratory and industrial processes.

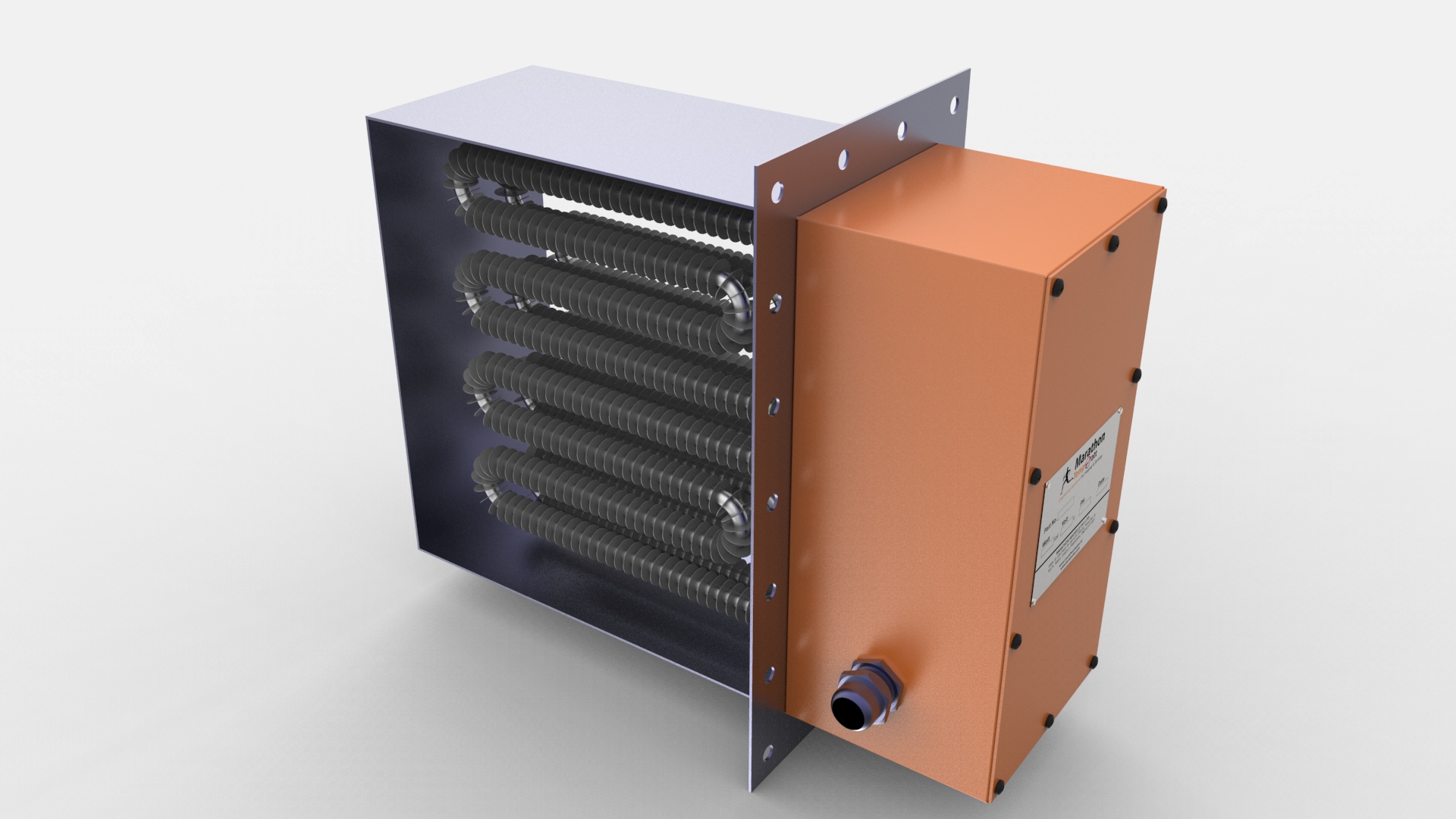

Control Panel

Control panels are, by far, the most reliable and steady solution for controlling the heating system. Choosing a proper controller and panel design helps ensure a trouble free operation and regulation. In order to meet the demands of various process control applications, control panels can be entirely customized to meet targets. Installing a control panel with the heating system not only maintains the stability and the heat transfer efficiency of the heating system, it also provides safety and prevents issues such as overheating and chemical disintegrations.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.